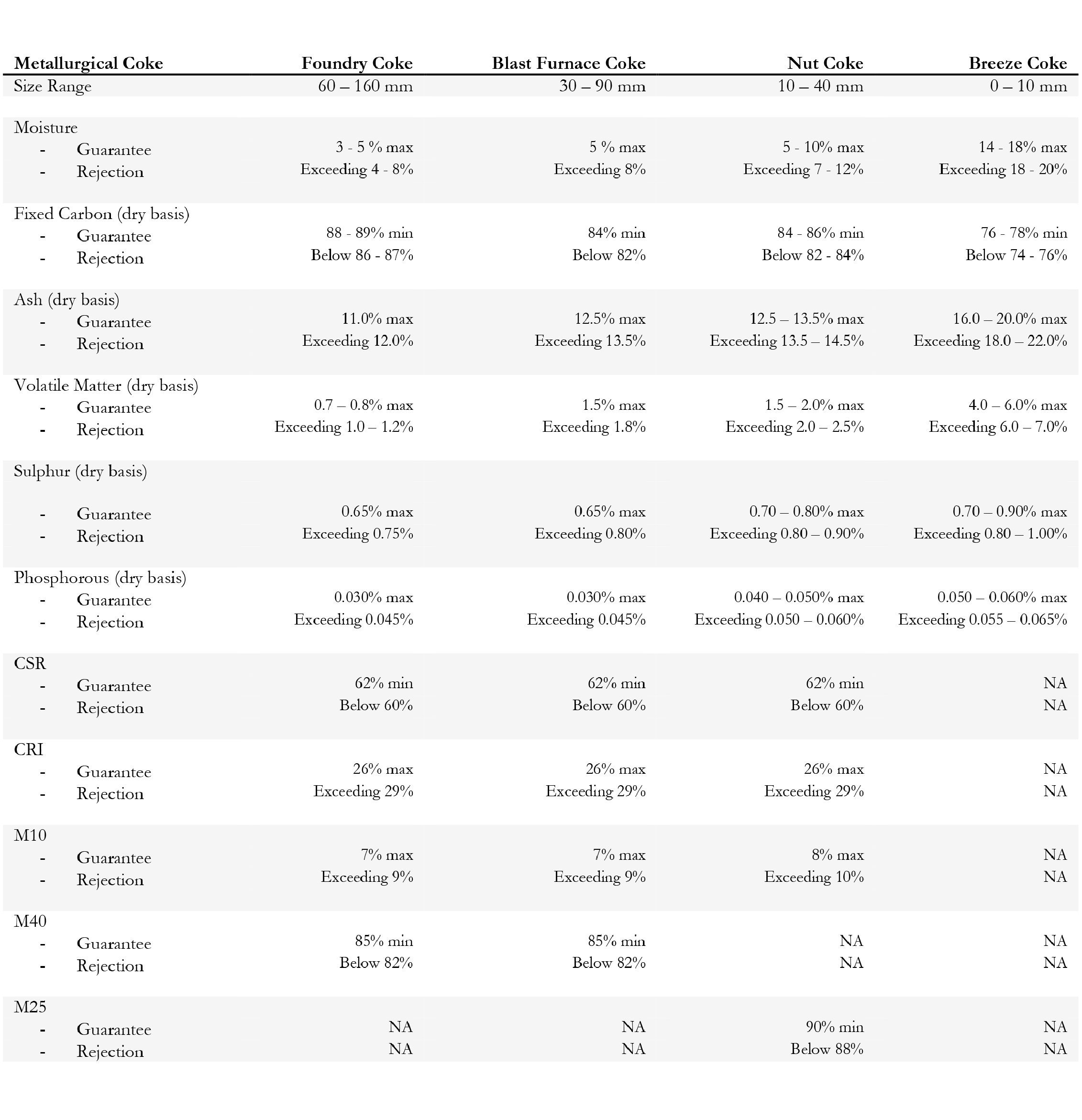

Metallurgical Coke Types offered by IGBR include but are not limited to:

- IGBR COKE BREEZE (0 – 10 MM)

- IGBR NUT COKE (20-40 MM; 15 – 35 MM; 10 – 30 MM; 10 – 25 MM; 5 – 20 MM)

- IGBR BLAST FURNACE COKE (30 – 80 MM; 30 – 90 MM; 40 – 90 MM)

- IGBR FOUNDRY COKE (90 – 150 MM)

The quality of the constituent coals determines the quality of the resulting coke. Good quality metallurgical coke is generally made from carbonization of good quality coking coals. Coking coals are defined as those coals that on carbonization pass through softening, swelling, and re-solidification to metallurgical coke. High quality coals produce coke that has the highest stability and CSR (coke strength after reactivity) to support the blast furnace and allow maximum production.

IGBR metallurgical coke is manufactured through destructive distillation of a blend of selected high-grade metallurgical coal. This carbonisation of coal occurs at 1,100 ⁰ C. Coking coals upon carbonisation go through softening, swelling and re-solidification to form coke.